Concrete is everywhere: in buildings, roads, sidewalks, bridges and foundations for almost every structure imaginable. We make more concrete than we do any other material on Earth, and that volume is rising because of global development, especially in China and India. Cement—the powdery binder that holds the sand or crushed stone in concrete together—is one of the most energy-intensive products on the planet. Limestone used in it is baked at up to 1,450 degrees Celsius (2,640 degrees Fahrenheit) in enormous kilns that are fired almost exclusively with fossil fuels. The chemical reactions involved produce even more carbon dioxide as a by-product. Making one kilogram of cement sends one kilogram of CO2 into the atmosphere. Worldwide every year cement and concrete production generates as much as 9 percent of all human CO2 emissions.

Societies have made cement and concrete in pretty much the same way for a century. Trials have shown that a portion of the cement in a mix can be replaced with calcined (burnt) clay or ingredients made from wastes such as fly ash and slag without a loss of strength but with fewer emissions. There is not enough supply to meet demand, but such alternatives can reduce CO2 to an extent.

Other alternative materials and processes can cut emissions significantly. Some are already spreading; others are experimental. Because most cement and concrete is made locally or regionally, close to where it is used, the availability of substitute materials, revised building standards to allow their use, capital costs for retooling and market acceptance are all practical challenges.

Credit: Jen Christiansen

BETTER CEMENT PRODUCTION

Cement manufacturing consumes large amounts of energy, much of it from fossil fuels that emit CO2. Certain steps also emit CO2 directly, notably, the creation of lime (step 3) and then clinker, a hardening agent (step 4). Replacing fossil fuels with renewable energy sources and raising efficiency across production could reduce the carbon footprint by up to 40 percent. Using different raw materials for clinker could dramatically lower the remaining 60 percent of carbon emissions. (The process shown is for so-called dry kilns; they have widely replaced wet kilns, which use even more energy.)

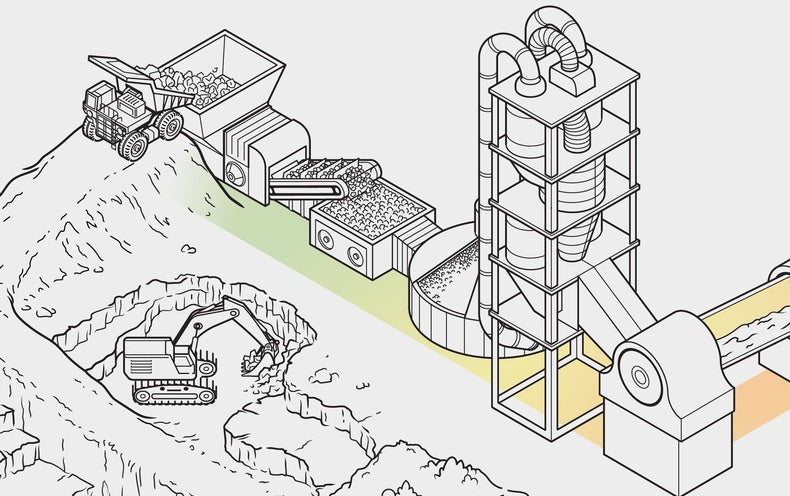

1. Mine and Grind Limestone

How it works: Deposits containing calcium carbonate, such as limestone or chalk, are mined from quarries, which may include small amounts of clay containing silicon, aluminum or iron. The ingredients are crushed into pieces less than 10 centimeters in size and then milled into a powder called raw meal.

Room to improve: Start with basalt instead of limestone or use “carbon-negative limestone” produced with waste CO2 (step 2), reducing emissions by up to 60 to 70 percent.

Credit: Nick Bockelman

2. Preheat Raw Meal …

How it works: Raw meal in a chamber above a kiln is heated to temperatures as high as 700 degrees C by the kiln’s hot, swirling exhaust gases, driving off moisture.

Room to improve: Burn oxygen-rich air to lessen CO2 emissions. Add equipment to capture CO2, which could reduce emissions by up to 60 percent. Use the waste CO2 to make carbon-negative limestone (step 1). Burn biomass or waste to heat the kiln instead of fossil fuel.

Credit: Nick Bockelman

3. … and Convert Meal into Lime

How it works: Preheated meal is burned in a combustion chamber immediately above and inside the top of the kiln at 750 to 900 degrees C, converting calcium carbonate to calcium oxide (quicklime) and CO2. This step accounts for 60 to 70 percent of the CO2 driven out of the raw materials and consumes about 65 percent of all fuel used in the entire cement production process.

Room to improve: Burn oxygen-rich air to lessen CO2 emissions. Add equipment to capture CO2. Use an electric kiln run on renewable energy, reducing emissions for steps 2, 3 and 4 by 30 to 40 percent.

Credit: Nick Bockelman

4. Convert Lime into Clinker

How it works: Lime is burned at up to 1,450 degrees C in a kiln rotating three to five times per minute. This process melts and sinters (fuses) the lime into Portland cement clinker—dark gray nodules three to 25 millimeters in diameter—and drives off more CO2. Clinker is the binder that causes cement to harden when it reacts with water.

Room to improve: Add a mineralizer such as calcium fluoride or sulfate to lower the lime’s melting temperature, saving energy.

Credit: Nick Bockelman

5. Cool and Store Clinker

How it works: Hot clinker is run across grates where air blowers cool it to about 100 degrees C. Once cool, it is stored in a silo and can last a long time without degrading, so it may be sold as its own commodity.

Room to improve: Electrify the process or pipe in waste heat from step 3 for initial cooling.

Credit: Nick Bockelman

6. Blend Clinker with Gypsum

How it works: Clinker is mixed with gypsum at a ratio of 20 or 25 to one.

Room to improve: Electrify the process.

Credit: Nick Bockelman

7. Grind the Blend into Portland Cement

How it works: Roller mills or ball mills grind the clinker and gypsum into a fine gray powder known as Portland cement.

Room to improve: Add finely ground limestone to replace up to 35 percent of the cement, reducing emissions created during earlier production steps. This mix is known as Portland-limestone cement. Create “blended cements” by adding fly ash (20 to 40 percent), slag (30 to 60 percent) or calcined clay (20 to 30 percent) to lower the clinker-to-cement ratio, reducing emissions by similar percentages.

Credit: Nick Bockelman

8. House Cement in Silos

How it works: The powder is thoroughly mixed so it is uniform throughout and is then stored in a silo. It will be packed into bags for retail sale or loaded into trucks headed for concrete mix facilities.

Room to improve: Consider lower-carbon alternatives to Portland cement for certain applications. These alternatives include alkali-activated cements and biocements generated by algae or microbes, as well as cements made from magnesium phosphate, calcium aluminate or calcium sulfoaluminate. Such options can reduce emissions for the entire process by 40 percent or more.

Credit: Nick Bockelman

BETTER CONCRETE PRODUCTION

Concrete is usually made at or near a construction site. Optimizing structural designs can reduce the amount of concrete needed (step 3). Reusing and processing concrete after demolition (step 4) can absorb CO2 from the atmosphere, offsetting some emissions from the original cement production.

1. Mix Cement, Water and Aggregate

How it works: Cement is mixed with specific amounts of water and aggregate such as sand, gravel or crushed stone at ambient temperature until a desired fluidic consistency is reached. About 80 percent of the mix is aggregate.

Room to improve: Change conveyors and mixers to run on renewable electricity, greatly reducing emissions. Include an additive such as biochar or algae to increase the concrete’s strength or tailor its workability or setting time, reducing emissions by 1 to 5 percent or more.

Credit: Nick Bockelman

2. Transport to Job Site

How it works: Concrete is mixed inside a drum-mixer truck that transports it to a construction site.

Room to improve: Switch to electric trucks. Minimize, collect and upcycle waste concrete into other precast materials such as highway barriers.

Credit: Nick Bockelman

3. Build a Structure

How it works: Building design dictates the shape, volume and strength of concrete elements needed.

Room to improve: Optimize structural designs so concrete is not wasted. Switch specifications from requiring minimum amounts of cement in the concrete to requiring a given compressive strength, which can reduce the necessary cement content. Change building codes to allow for new, alternative and blended cements. Rely on concrete’s ability to gain strength over time by specifying compressive strengths at two or three months instead of the common one month, which can lessen the amount of material needed.

Credit: Nick Bockelman

4. Plan End of Life

How it works: Demolished concrete is often dumped into landfills or crushed and used as a base material for roads and highways.

Room to improve: Design for deconstruction so concrete’s elements can be reused in whole or in part. If concrete is demolished, grind it and spread it thinly to maximize its surface area and expose it to air for as long as possible to absorb CO2. With years of exposure, concrete can absorb perhaps as much as 17 percent of the CO2 emitted when the cement for that concrete was manufactured.

Credit: Nick Bockelman

Read The Full Article Here